Wind turbines: they’re not just for sprawling wind farms anymore. More and more homeowners are exploring residential wind energy as a way to reduce their carbon footprint and gain greater energy independence. But like any piece of machinery, a home wind turbine requires regular care to ensure optimal performance and longevity. Ignoring maintenance can lead to decreased energy production, costly repairs, and even premature failure of the entire system.

Proper maintenance is the key to unlocking the full potential of your home wind turbine investment. It's about maximizing energy output, extending the lifespan of your equipment, and ensuring the safety of your property. A well-maintained turbine operates more efficiently, generating more power and saving you money in the long run. Plus, regular inspections can identify small issues before they escalate into major, expensive problems.

A simple yet crucial first step? Get to know your turbine’s user manual inside and out. It contains vital information specific to your model, including recommended maintenance schedules and safety precautions.

Your Seasonal Wind Turbine Maintenance Checklist

Maintaining a wind turbine is a year-round commitment, but focusing on seasonal checks helps to address specific weather-related concerns. This structured approach ensures you're proactively caring for your investment, whatever the time of year.

Spring: Spring is the season of renewal, making it the perfect time for a thorough inspection after the harsh winter months.

Blade Inspection: Check the blades for any signs of damage, such as cracks, chips, or erosion. Even small imperfections can affect aerodynamic performance. Look for delamination, especially on the leading edges.

Action: Clean the blades with a mild detergent and water. For minor damage, consider using a specialized epoxy repair kit designed for wind turbine blades. For significant damage, consult a professional. Tower and Foundation Check:Inspect the tower for rust, corrosion, or structural damage. Examine the foundation for cracks or settling.

Action: Treat any rust with a rust converter and apply a protective coating. If you find cracks in the foundation, consult a structural engineer. Electrical Connections:Examine all electrical connections for tightness and corrosion. Clean any corroded terminals and tighten any loose connections.

Action: Use a multimeter to check voltage and current levels to ensure they are within the turbine's specifications. Lubrication:Lubricate all moving parts, such as bearings and yaw mechanisms, according to the manufacturer's recommendations.

Action: Use the correct type of grease or oil as specified in the turbine's manual. Over-greasing can be as detrimental as under-greasing.

Summer: Summer brings heat and sometimes intense storms. Focus on preventing overheating and protecting against lightning.

Cooling System Check: If your turbine has a cooling system, ensure it is functioning correctly. Check for leaks and ensure the coolant level is adequate.

Action: Clean any dust or debris that may be blocking the cooling fins. Replace coolant if necessary. Lightning Protection:Verify that your lightning protection system is properly grounded and functioning correctly.

Action: Test the grounding system with a ground resistance meter. Ensure all surge protectors are in good working order. Lubrication (Again):High temperatures can degrade lubricants more quickly. Consider a mid-season lubrication check.

Action: Monitor bearing temperatures. If they are running hotter than usual, relubricate.

Autumn: Autumn is the time to prepare your turbine for the coming winter.

Blade Inspection (Again): Conduct another blade inspection, paying close attention to any damage that may have occurred during the summer storms.

Action: Address any blade damage promptly to prevent it from worsening over the winter. Bolt Tightening:Check and tighten all bolts and fasteners on the tower, blades, and nacelle. Temperature fluctuations can cause bolts to loosen.

Action: Use a torque wrench to ensure proper tightening. Consult the turbine's manual for recommended torque values. Gearbox Inspection:If your turbine has a gearbox, check the oil level and condition. Replace the oil if it is dirty or contaminated.

Action: Send an oil sample to a lab for analysis to check for wear particles.

Winter: Winter brings cold temperatures, snow, and ice, all of which can put a strain on your wind turbine.

Ice Prevention: If you live in an area with heavy snowfall or ice, consider installing an anti-icing system.

Action: Regularly inspect the blades for ice buildup. Remove ice carefully using a soft brush or de-icing solution.Neveruse sharp objects that could damage the blades. Bearing Inspection:Cold temperatures can increase the viscosity of lubricants, making it harder for bearings to rotate.

Action: Monitor bearing temperatures. If they are running colder than usual, consider using a lower-viscosity lubricant. Electrical System:Check the electrical system for any signs of moisture or corrosion.

Action: Ensure all enclosures are properly sealed to prevent moisture from entering.

DIY vs. Professional Wind Turbine Maintenance

One of the biggest questions homeowners face is whether to tackle wind turbine maintenance themselves or hire a professional. The answer depends on your comfort level, experience, and the complexity of your system. Some tasks, like visual inspections and basic cleaning, are well within the capabilities of most DIY enthusiasts. More complex tasks, such as electrical repairs, gearbox maintenance, and blade repairs, are best left to qualified technicians.

DIY Maintenance

Pros: Cost-effective, convenient, allows you to learn more about your system. Cons: Requires time, knowledge, and tools. Can be risky if not done correctly. Suitable Tasks:Visual inspections, blade cleaning, lubrication (if comfortable), bolt tightening, basic electrical checks.

Professional Maintenance

Pros: Ensures safety, thoroughness, and expertise. Can identify and address potential problems before they become serious. Cons: More expensive. Requires scheduling appointments. Suitable Tasks:Blade repairs, gearbox maintenance, electrical repairs, tower inspections, any task involving heights or specialized equipment.

The Hybrid Approach

Many homeowners opt for a hybrid approach, performing basic maintenance tasks themselves while hiring a professional for more complex inspections and repairs. This can be a good way to save money while still ensuring the safety and reliability of your wind turbine. Consider scheduling a professional inspection at least once a year, even if you handle most of the routine maintenance yourself. The home wind turbine cost will be lower in the long run with periodic professional inspections.

Essential Tools and Equipment for Wind Turbine Maintenance

Having the right tools and equipment is essential for performing wind turbine maintenance safely and effectively. Here's a list of some of the most important items: Safety Gear:

Hard hat

Safety glasses

Gloves

Safety harness (for working at heights)

Non-slip footwear Cleaning Supplies:

Mild detergent

Water

Soft brushes

Sponges

Rags Lubrication Equipment:

Grease gun

Oil can

Various lubricants (as specified by the manufacturer) Electrical Tools:

Multimeter

Wire strippers

Crimpers

Voltage tester Mechanical Tools:

Wrench set

Socket set

Torque wrench

Screwdriver set

Pliers Inspection Tools:

Binoculars

Flashlight

Inspection mirror

Borescope (for inspecting hard-to-reach areas) Miscellaneous:

Ladder or scaffolding (for accessing the turbine)

Work platform

First-aid kit

Before starting any maintenance task, be sure to disconnect the turbine from the grid and follow all safety precautions. Always consult the turbine's manual for specific instructions and recommendations.

People Also Ask:

How often should I inspect my home wind turbine?

A visual inspection should be performed at least monthly, looking for any obvious signs of damage or wear. A more thorough inspection, including lubrication and bolt tightening, should be done at least twice a year, ideally in the spring and fall. A professional inspection is recommended annually. This frequency can vary depending on the turbine model, environmental conditions, and usage patterns.

What are the most common problems with small wind energy for homes?

Common problems include blade damage, bearing failure, electrical connection issues, and gearbox problems. Improper installation, inadequate maintenance, and extreme weather conditions can all contribute to these issues. Regular inspections and proactive maintenance can help prevent these problems and extend the lifespan of your turbine.

How can I maximize the energy output of my wind turbine?

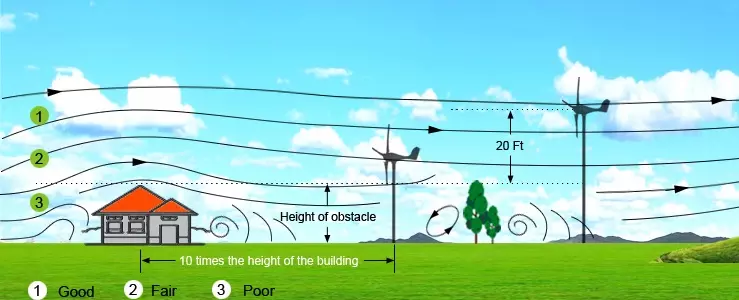

To maximize energy output, ensure your turbine is properly sited in an area with consistent winds. Keep the blades clean and free of damage. Regularly lubricate all moving parts. Address any mechanical or electrical issues promptly. Consider upgrading to a more efficient turbine model.

What is the average lifespan of a residential wind turbine?

With proper maintenance, a residential wind turbine can last for 20-30 years or more. However, the lifespan can be significantly reduced by neglect or improper operation.

Are there any tax incentives or rebates for wind turbine maintenance?

Tax incentives and rebates vary depending on your location and the specific program. Check with your state and local government agencies, as well as your utility company, to see if any incentives are available. Some incentives may cover a portion of the cost of wind turbine installation and maintenance.

Maintaining a home wind turbine might seem daunting, but with a little knowledge, planning, and effort, you can keep your system running smoothly and efficiently for years to come. Embrace the process. Enjoy the satisfaction of generating your own clean energy. And remember, a well-maintained turbine is a testament to your commitment to a sustainable future. You've got this!